An innovative solution for reliable seismic performance of pallet racking systems

Storage racking systems are increasingly being installed in regions with high earthquake risk. However, they remain vulnerable to collapse, as seen in recent seismic events. Traditional solutions such as base isolation techniques are often expensive or limit functionality.

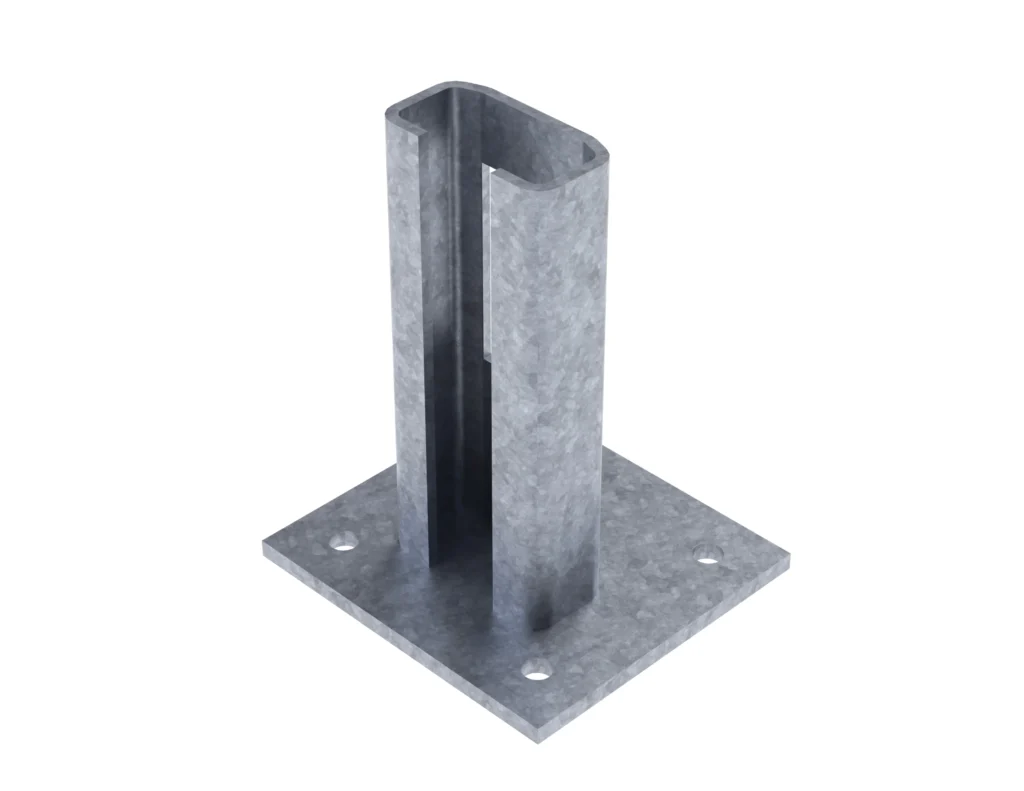

To address this, Dexion has developed an earthquake-resistant baseplate called the Friction Slipper Baseplate, designed to manage the seismic demand of pallet racking systems. The baseplate has demonstrated excellent performance through extensive experimental studies, from component tests to full-scale shaking table tests, and is comparable in cost to standard, non-seismic baseplates.

Why It Matters

Around 40% of all goods are stored on racks at some point during the manufacture-to-consumption logistics cycle. In 2017, goods worth USD 16.5 billion were stored on cold-formed steel racking systems in seismically active regions worldwide.

These racks are highly susceptible to collapse during major earthquakes. In the 2010–2011 Christchurch earthquakes, approximately NZD100 million worth of goods stored on pallet racks were lost, with even greater losses from supply chain disruption. Similarly, during the 2011 Tōhoku earthquake in Japan, the loss of stored goods severely affected international supply chains, particularly in vehicle manufacturing.

From Research to Real-World Application

Dexion New Zealand has strongly supported the development of the product since its inception by Dr. Zhenghao Tang as part of his PhD research between 2015 and 2019. Dr. Tang was a joint PhD student at the University of Auckland (UOA) in New Zealand and the University of Wollongong (UOW) in Australia.

The product was successfully implemented in a commercial project in 2018, marking the beginning of its practical use. Today, about one-third of Dexion storage racking systems in New Zealand are equipped with the Friction Slipper Baseplate. This level of adoption highlights the strong market demand for safer and more efficient seismic solutions.

Dr. Tang is now the Director of Research and Development at Dexion New Zealand where he continues to enhance the organisation’s engineering capabilities.

About the Friction Slipper Baseplate

The Friction Slipper Baseplate revolutionises the seismic resilience of pallet racking systems. Supported by extensive experimental testing, it offers several significant advantages over existing systems:

- It allows the pallet rack to rock in a controlled manner, avoiding column overload while facilitating the dissipation of earthquake energy.

- It strengthens the columns at the bottom level to protect against bottom-storey collapse, which is a common failure mode observed in collapsed racks.

- It significantly increases damping (energy dissipation) and ductility, reducing the duration of swaying of the rack during an earthquake and enhancing resilience.

- It fits into the same footprint as conventional baseplates, ensuring no interference with daily operations.

- It is only slightly more expensive to produce than standard baseplates and is just as easy to install.

- Does not typically require replacement after a major earthquake, allowing racks to remain operational with minimal disruption to the business.

- Enables the use of smaller racking system members and thinner floor slabs, reducing overall warehouse construction costs.

Performance and Market Advantage

The Friction Slipper Baseplate allows seismic performance beyond that of standard racking systems. It outperforms conventional baseplates while remaining significantly more affordable than existing seismic isolation systems.

Typically, baseplates are custom designed by rack manufacturers for specific installations. Special systems, such as base isolators, are available but are often too costly for wide application.

The Friction Slipper Baseplate is compatible with other pallet racking systems and is an attractive option for new and existing installations at very competitive costs.

Research Background

The product was developed by Dr. Zhenghao Tang as part of his PhD research between 2015 and 2019. Dr. Tang was a joint PhD student at the University of Auckland (UOA) in New Zealand and the University of Wollongong (UOW) in Australia.

The research was supervised by Prof. G. Charles Clifton (University of Auckland), Prof. James Lim (University of Waikato), and Prof. Lip The (University of Wollongong).

Three academic papers have demonstrated the outstanding performance of the Friction Slipper Baseplate:

- “Increasing Seismic Resilience of Pallet Racking Systems Using Sliding Friction Baseplates” – NZSEE Conference, 2017

This study introduced the Friction Slipper Baseplate as a way to improve the seismic resilience of cold-formed steel pallet racks. Its performance was compared to conventional baseplates through component tests, full-scale push-over tests, and free-vibration tests. Results showed that racks fitted with the Friction Slipper Baseplate had significantly better seismic performance, with greater energy dissipation and lower force demand.

- “Seismic Performance of Pallet Racking System with Friction Slipper Baseplates in Cross-Aisle Direction” – International Conference on Thin-Walled Structures, 2023

This research focused on full-scale shaking table tests to evaluate how the Friction Slipper Baseplate performs under real earthquake conditions. Compared to standard baseplates, the system delivered a marked improvement in seismic resilience, reducing structural damage and preventing collapse even at high ground motion intensities. The study reinforces the baseplate’s potential to enhance the safety and reliability of pallet racking systems in earthquake-prone regions.

- “Recent Development on the Seismic Devices for Steel Storage Structures” – Thin-Walled Structures, Volume 155 (2020)

An international research group examined the latest innovations in seismic protection for steel storage structures, including energy dissipation and base isolation systems. The paper highlighted the Friction Slipper Baseplate, developed by Dr. Tang and his research team, as a novel energy-dissipating joint. Using controlled friction between the upright and a stub welded to the baseplate, it effectively absorbs seismic energy. Full-scale testing confirmed its superior performance compared to other baseplate joints, strengthening its case as a cost-effective, high-performance solution for seismic resilience.

Building Safer Storage Systems

The Friction Slipper Baseplate demonstrates that seismic resilience can be achieved without added cost or complexity. With proven performance and growing adoption, Dexion continues to lead innovation in safer, smarter, and more reliable storage systems for global market.